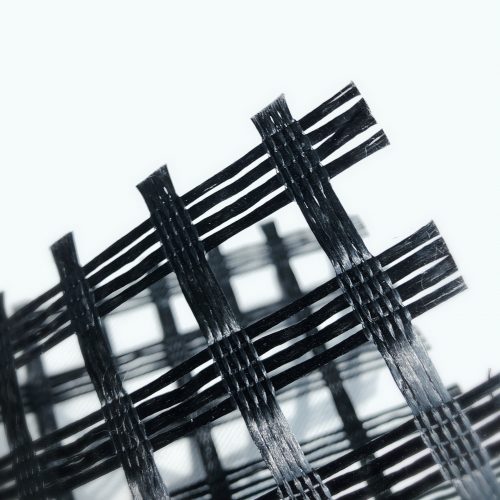

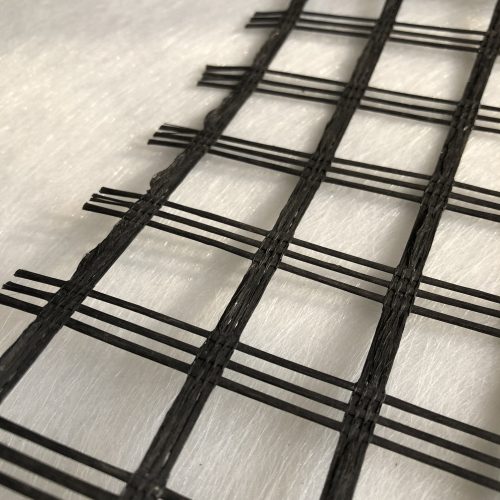

Polyester Geogrid

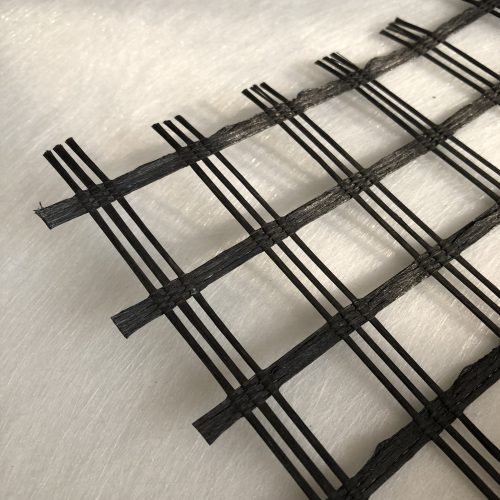

Polyester Geogrid known as PET Geogrid is woven by high strength polymer yarns as per desired mesh sizes and strength from 20kN/m to 800kN/m(Biaxial type), 40-25kN/m to 600-400kN/m(Uniaxial type).

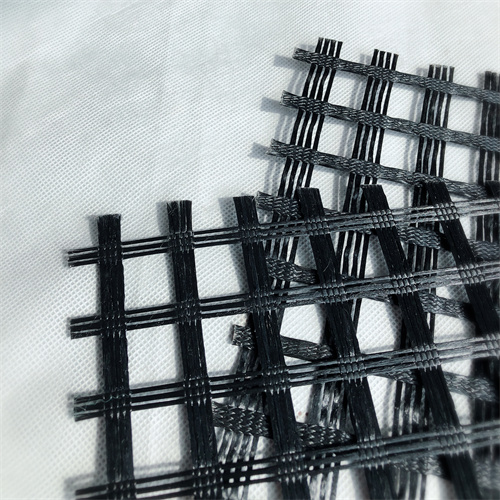

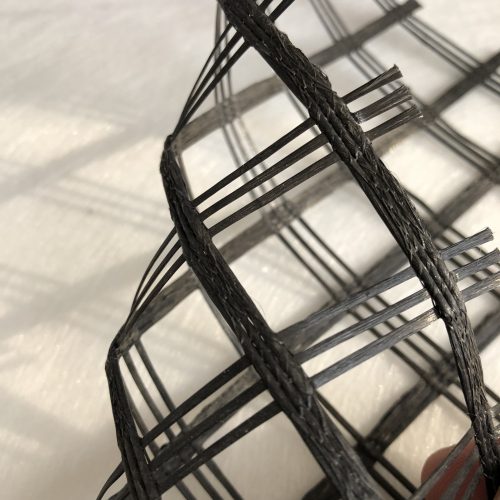

Polyester Geogrid is created through interlacing, usually at right angles, two or more yarns or filaments. Exterior of PET Grid is coated with polymer or nontoxic substance material for UV, acid and alkali resistance and prevents the bio-decomposition.

Polyester geogrid has good rutting resistant performance under high temperature. Polyester geogrid has a compact woven fabric structure. This structure constitutes a grid reinforcement system which exerts strong adhesive forces on the subgrade. Polyester geogrid can effectively enhance the bearing capacity of ground.

Polyester geogrid is widely introduced to the various fields of civil engineering, transportation engineering, and environment issues. The reinforced steep slopes, reinforced retaining earth walls, reinforced embankments, reinforced abutments and piers are typical applications where geogrids are used. The resulting grid structure possesses large openings that enhance interaction with filling material.

Product Features

The Warp Knitted Polyester Geogrid has the characteristics of high intension, low elongation ratio, erosion-resistant, aging-resistant,

high occlusive force with soil or gravel, light weight, water drainage and so on.

Product Function

- Reinforcing the embankment slope.

- Retaining walls reinforced to enhance the overall strength.

- Reinforcement, segregation of dam and river in water conservancy projects reinforce and the soft soil base, strength their projection and improve the bearing capacity and stability of the foundation.

- The soft soil roadbeds of road, railway and other municipal roads are reinforced which can effectively improve the strength of subgrade, delaying reflection cracks in the road.

Specifications

Polyester Geogrid Biaxial Type

Property | Test Method | PET 30/30 | PET 50/50 | PET 60/60 | PET 80/80 | PET 100/100 | PET 150/`150 | PET 200/200 | |||

Ultimate tensile strength( ≥kN/m) | MD | ASTM D 6637 | 30 | 50 | 60 | 80 | 100 | 150 | 200 | ||

| CD | 30 | 50 | 60 | 80 | 100 | 150 | 200 | ||||

Approximate Mesh Size(mm) | 12.7×12.7 25.4×25.4 40×40 50×50 | ||||||||||

After Treatment | PVC Soakage | ||||||||||

Elongation at maximum load (%) | MD | 10 | |||||||||

CD | 10 | ||||||||||

Temperature Resistant(℃) | -100~280 | ||||||||||

Resin Content (%) | ≤30 | ||||||||||

Resistance to Installation Damage %SC/%SW/%GP

| 95/93/90 | ||||||||||

Design Life(years) | 150 | ||||||||||

| PET Yarn Properties | |||||||||||

Carboxyl End Group(CEG) | mmol/kg | GRI GG7 | <30 | ||||||||

| Molecular Weight | Mn | GRI GG8 | >25000 | ||||||||