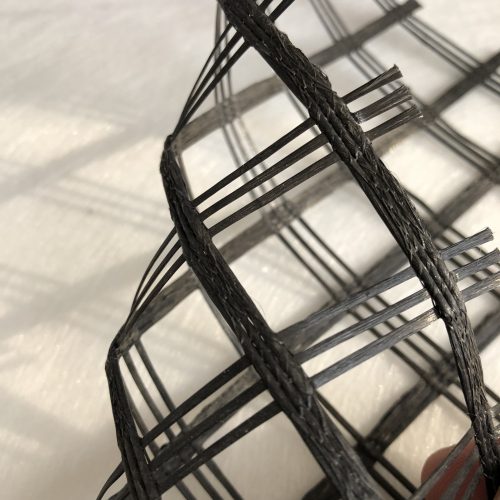

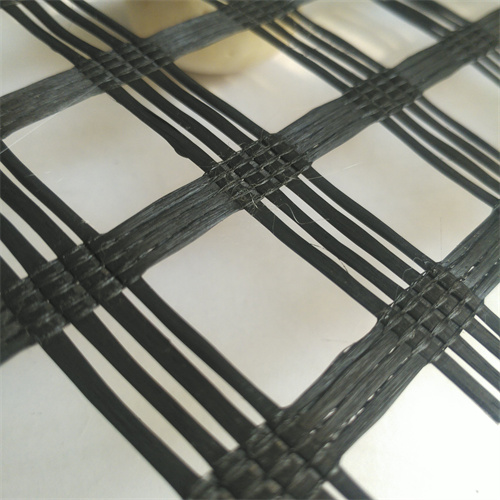

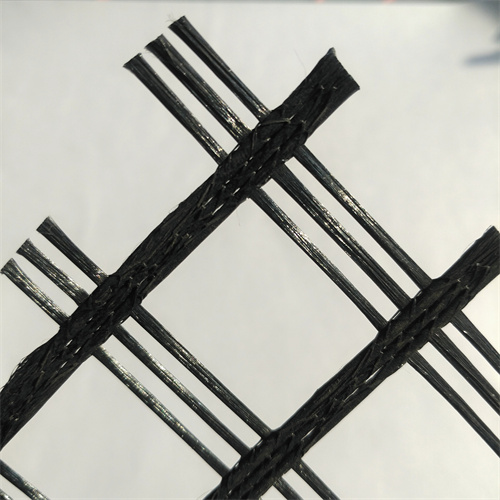

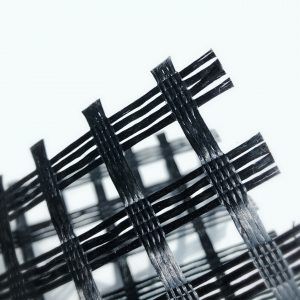

Polyester geogrid made with polyester yarns that have a high molecular weight and extraordinary tensile strength, our Polyester Uniaxial Geogrid is a high-performance soil reinforcement product primarily used for slope stabilization and retaining wall installations. The polyester yarns are knitted into a dimensionally stable network of apertures to form the geometric grid shape offering tensile reinforcement to the soil in both the vertical and horizontal directions. Polyester Uniaxel Geogrid is coated with a black saturation coating to provide further chemical and mechanical benefits that preserve its durability in any environment.

Geogrid retaining walls have revolutionized the field of civil engineering, offering effective solutions for stabilizing slopes and retaining soil. Among the various types of geogrids available, polyester geogrids stand out as a popular and versatile choice. In this comprehensive guide, we will delve into the world of geogrid retaining walls, focusing on the best polyester geogrids and their pricing.

Product Function

- Reinforcing the embankment slope.

- Retaining walls reinforced to enhance the overall strength.

- Reinforcement, segregation of dam and river in water conservancy projects reinforce and the soft soil base, strength their projection and improve the bearing capacity and stability of the foundation.

- The soft soil roadbeds of road, railway and other municipal roads are reinforced which can effectively improve the strength of subgrade, delaying reflection cracks in the road.

Specifications

Polyester Geogrid Uniaxial Type

Property | Test Method | PET 60/30 | PET 80/30 | PET 100/30 | PET 150/30 | PET 180/30 | PET 250/30 | PET 300/30 | |||

Ultimate tensile strength( ≥kN/m) | MD | ASTM D 6637 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | ||

| CD | 60 | 80 | 100 | 150 | 180 | 250 | 300 | ||||

Approximate Mesh Size(mm) | 12.7×12.7 25.4×25.4 40×40 50×50 | ||||||||||

After Treatment | PVC Soakage | ||||||||||

Elongation at maximum load (%) | MD | 12 | |||||||||

CD | 12 | ||||||||||

Temperature Resistant(℃) | -100~280 | ||||||||||

Resin Content (%) | ≤30 | ||||||||||

Resistance to Installation Damage %SC/%SW/%GP

| 95/93/90 | ||||||||||

Design Life(years) | 150 | ||||||||||

| PET Yarn Properties | |||||||||||

Carboxyl End Group(CEG) | mmol/kg | GRI GG7 | <30 | ||||||||

| Molecular Weight | Mn | GRI GG8 | >25000 | ||||||||