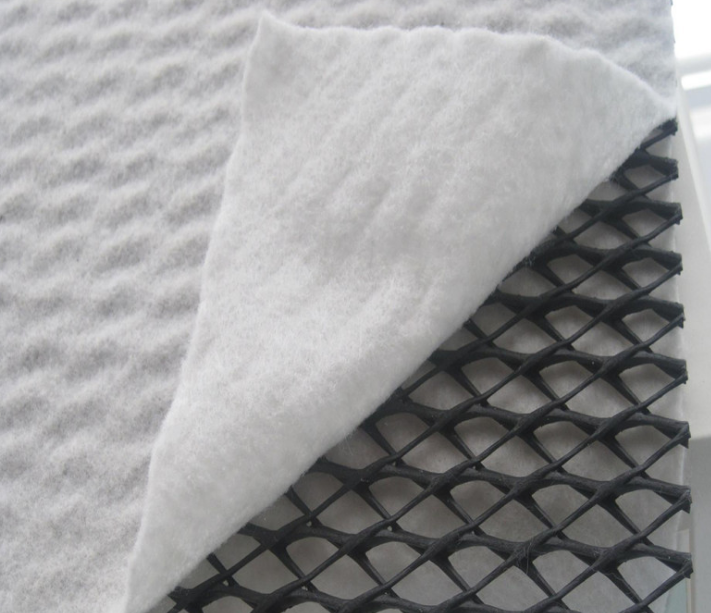

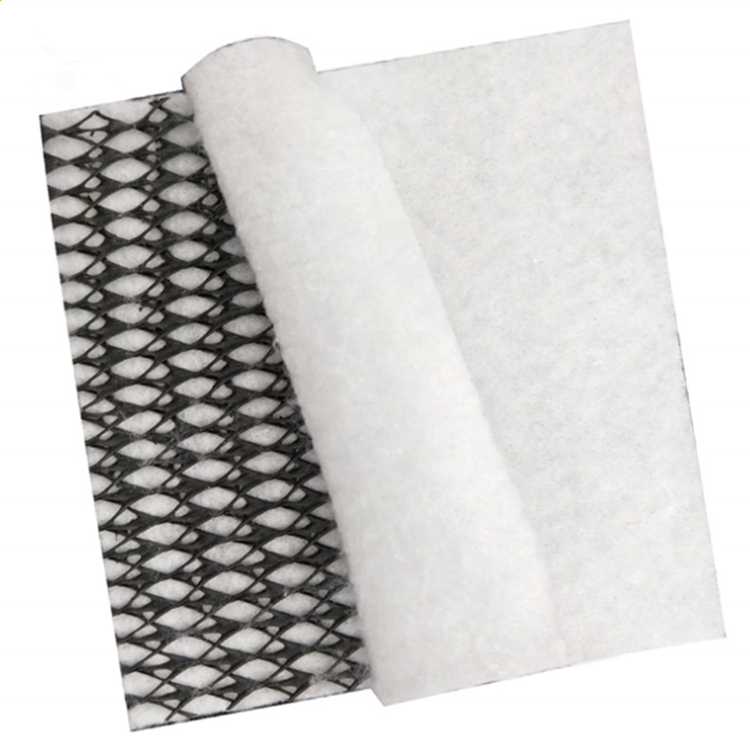

The ProNet geonet geocomposite uses quality, polypropylene (PP) nonwoven geotextiles and quality, high density polyethylene (HDPE)

resins in the manufacture of the geocomposite drain. The geotextile may be supplied in a range of weights for optimal performance and

can be laminated in either a single or double sided configuration to the geonet. The geotextiles used in the manufacture of the ProNet

Geocomposites are resistant to ultraviolet degradation, rotting,biological degradation, and naturally encountered acids and alkalis

within the range of pH 2-13. Both polypropylene and HDPE are recognised as being highly resistant to landfill leachate and other

aggressive solutions..

BENEFITS of GEONETS GEOCOMPOSITES

- Stable geonet and grid structure manufactured from polymers that are highly resistant to deterioration from a wide range of

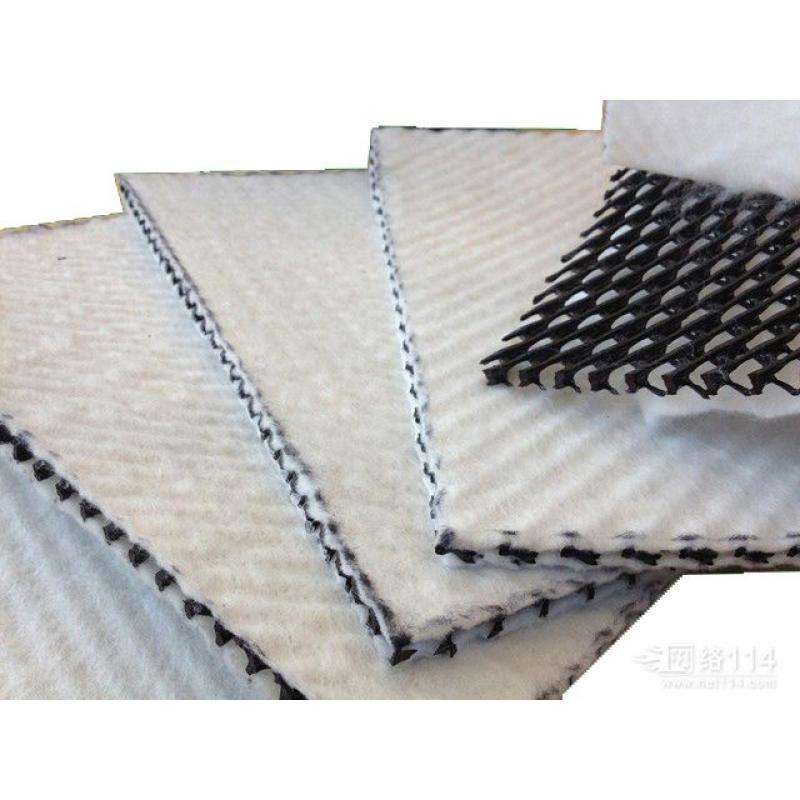

aggressive solutions. - High quality nonwoven geotextile available in a range of weights and filtration characteristics that is factory bonded to the geonet

structure. - Polypropylene non woven geotextile proven to be highly durableto a wide range of leachate types.Ability to custom manufacture drainage product to specific client’s requirements.

- Wide width rolls to minimise installation costs.

- One composite product that minimises installation time in the field. When required, the geonet can be laminated to a geotextile

saving labour time and resources in the field. Lamination can be carried out to one or both geonet faces dependant upon the

application of use. - Unique biplanar drainage structure for flow in all directions. Flow is unrestricted unlike other profiles.

- High flow capacity under very high loads.

- Economical alternative to traditional granular drainage layers

Application:

- LANDFILL DRAINAGE SYSTEMS

- LANDFILL LEAK DETECTION SYSTEMS

- MEMBRANE PROTECTION

- LANDFILL CAP DRAINAGE SYSTEMS

- LEACHATE COLLECTION & REMOVAL

- GAS VENTING SYSTEMS

Specification:

Item | Unit | standard value | ||||

1200g | 1400g | 1600g | 1800g | 2000g | ||

Complex unit area mass | g/m2 | ≥1200 | ≥1400 | ≥1600 | ≥1800 | ≥2000 |

Complex thickness | mm | ≥6.0 | ≥7.0 | ≥8.0 | ≥9.0 | ≥10.0 |

Composite longitudinal tensile strength | kn/m | ≥16.0 | ≥16.0 | ≥16.0 | ≥16.0 | ≥16.0 |

Composite water conductivity | m2/s | ≥1.2×10-4 | ≥1.2×10-4 | ≥1.2×10-4 | ≥1.2×10-4 | ≥1.2×10-4 |

Peel strength of core and non-woven fabric | kn/m | ≥0.3 | ≥0.3 | ≥0.3 | ≥0.3 | ≥0.3 |

Core thickness | mm | ≥5.0 | ≥5.0 | ≥5.0 | ≥5.0 | ≥5.0 |

Net core tensile strength | kn/m | ≥13.0 | ≥15.0 | ≥15.0 | ≥15.0 | ≥15.0 |

Non-woven fabric unit area quality | g/m2 | ≥200 | ≥200 | ≥200 | ≥200 | ≥200 |

Non-woven fabric normal permeability coefficient | cm/s | ≥0.3 | ≥0.3 | ≥0.3 | ≥0.3 | ≥0.3 |