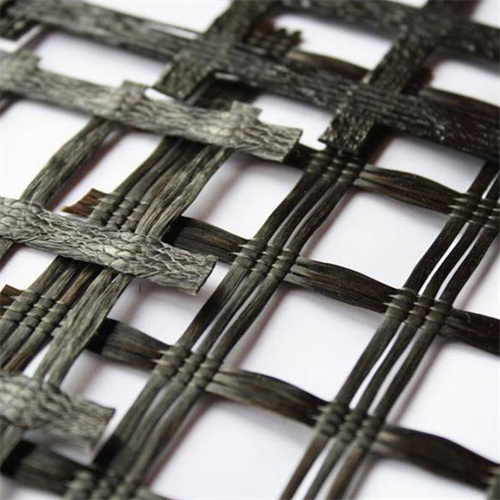

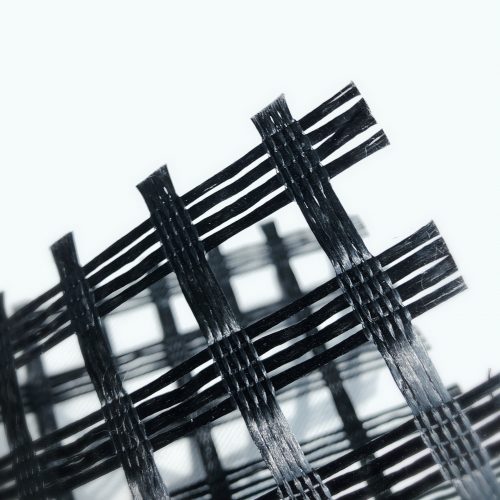

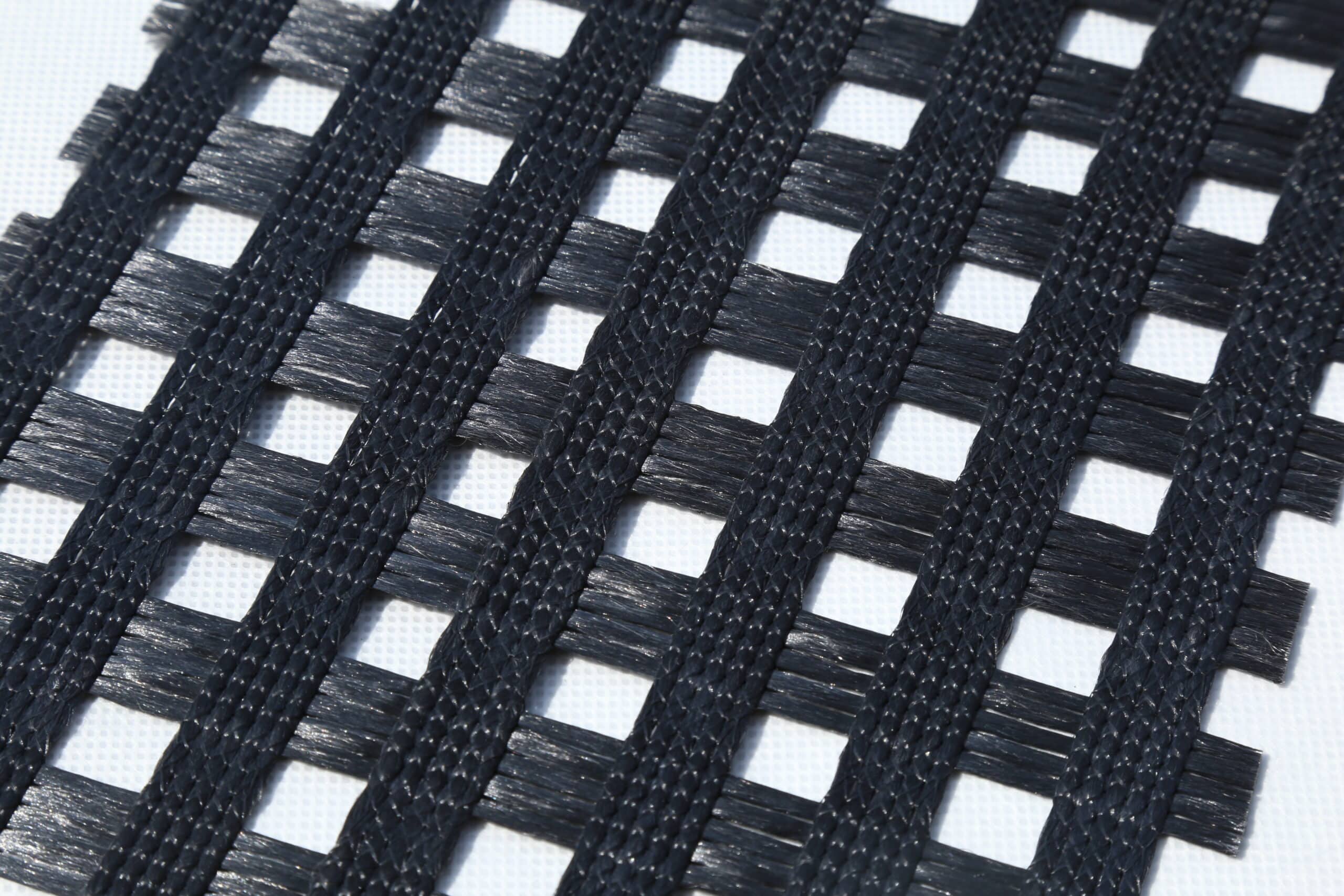

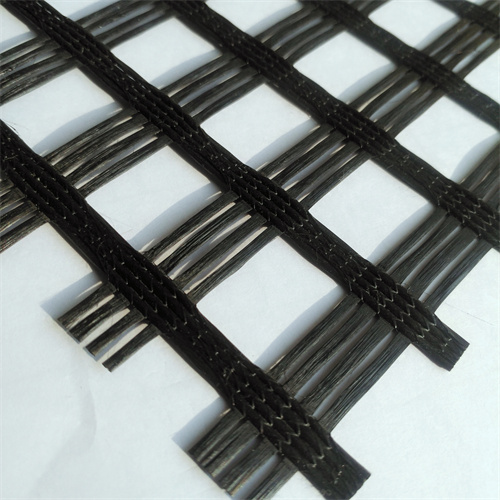

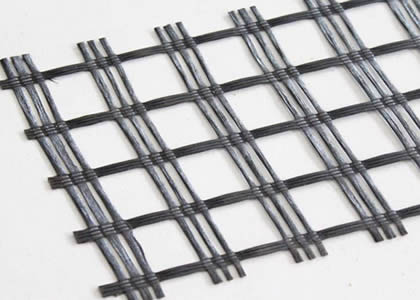

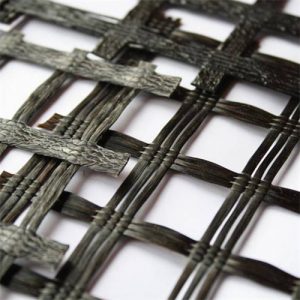

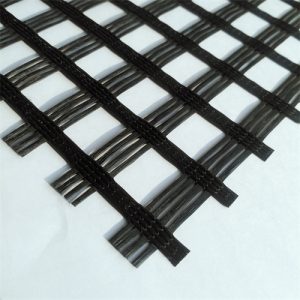

Fiberglass Geogrid is a versatile geosynthetic material designed to enhance the mechanical strength and durability of soil, asphalt, and concrete structures. Made from alkali-free fiberglass yarn coated with high-quality modified asphalt or PVC, this grid structure offers unparalleled tensile strength, low elongation, and excellent resistance to environmental factors. Its unique warp-knitted design ensures optimal load distribution and stability, making it a preferred choice for various civil engineering applications.

Key Advantages

- High Tensile Strength: With longitudinal and transverse strengths ranging from 25 to 200 KN/m, it provides robust reinforcement for roads, railways, and retaining walls.

- Low Elongation & Creep Resistance: The modified asphalt coating minimizes long-term deformation, ensuring long-term performance even under heavy loads.

- Corrosion & Chemical Resistance: Ideal for harsh environments, including coastal areas and industrial sites, as it withstands UV exposure, alkali, and acid conditions

- Versatile Applications

- Road Construction: Prevents pavement cracking, extends lifespan, and distributes stress in asphalt overlays and old cement roads.

- Erosion Control: Stabilizes slopes, riverbanks, and embankments by reducing soil erosion and enhancing water retention.

- Infrastructure Projects: Used in tunnel linings, airport runways, and retaining walls for added structural integrity.

- Ease of Installation & Cost-Effectiveness

- Lightweight and flexible design allows for quick construction without heavy machinery.

- Reduces maintenance costs by delaying reflective cracking and extending the service life of surfaces.

- Mesh Size: Available in 12.7×12.7 mm to 50×50 mm, catering to different project requirements.

- Width & Length: Customizable up to 6 meters wide and 300 meters long.

- Temperature Resistance: Operates effectively from -100°C to 280°C, suitable for extreme climates.

| Propertiesspecifications | TGSB25-25 | TGSB30-30 | TGSB40-40 | TGSB50-50 | TGSB80-80 | TGSB100-100 | |

| Strength (KN / m) | Longitudinal | 25 | 30 | 40 | 50 | 80 | 100 |

| Transverse | 25 | 30 | 40 | 50 | 80 | 100 | |

| Elongation at break% | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | |

| Grid (mm) | 12.5×12.5 12.7×12.7 25×25 25.4×25.4 25.7×25.7 30×30 40×40 50×50 | ||||||

| Width (m) | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | |

Product specifications and performance parameters (glass fiber geogrid self-adhesive type) |

| Properties specifications | EGA50-50 | EGA60-60 | EGA80-80 | EGA100-100 | EGA120-120 | EGA150-150 | |

| Strength (KN / m) | Longitudinal | 50 | 60 | 80 | 100 | 120 | 150 |

| Transverse | 50 | 60 | 80 | 100 | 120 | 150 | |

| Elongation at break% | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | |

| Grid (mm) | 12.5×12.5 12.7×12.7 25×25 25.4×25.4 25.7×25.7 30×30 40×40 50×50 | ||||||

| Width (m) | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | |

Quality Assurance & Certifications

Complies with international standards such as ISO 9001, ISO 14001, and CE, ensuring consistent quality.

Backed by comprehensive after-sales support, including technical training, site inspections, and replacement services for damaged products.

Why Choose Fiberglass Geogrid?

For over three decades, fiberglass geogrids have proven their efficacy in over 100 countries, from enhancing highway durability to stabilizing critical infrastructure35. Partner with leading manufacturers like www.geosintetic.com to access competitive pricing, fast delivery, and tailored solutions for your project needs.

Contact Us Today for a Free Quote!