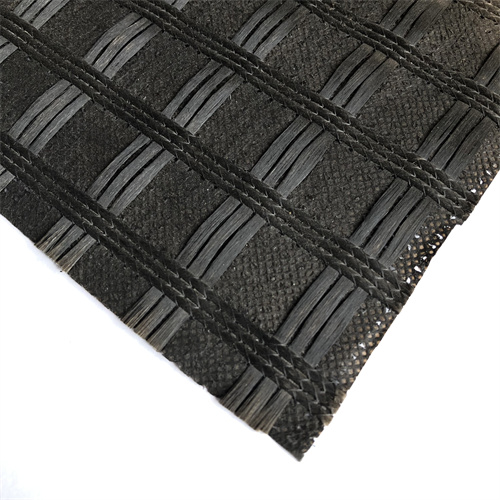

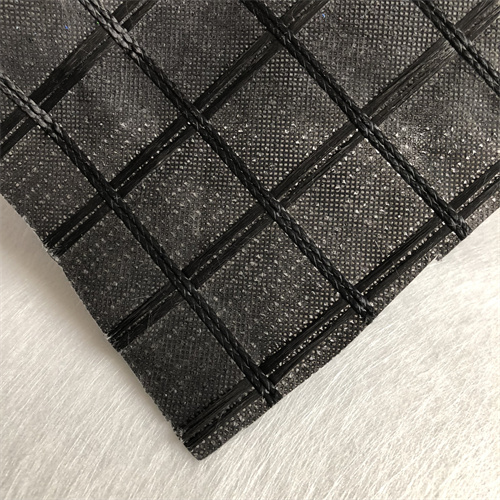

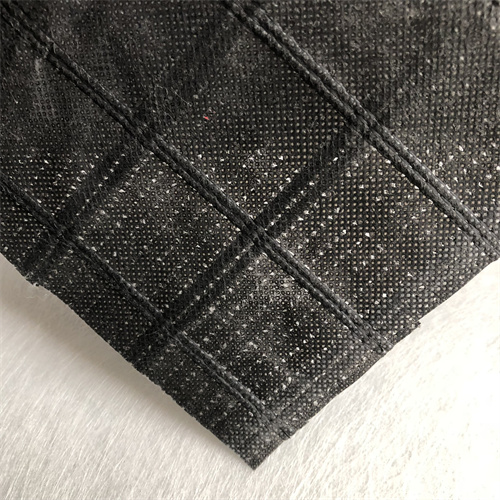

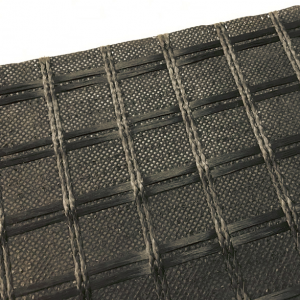

Asphalt geocomposites are geocomposites constructed by a high-tenacity fiberglass grid, a lightweight nonwoven geotextile and bitumen coating which can provide a good bonding property with asphalt layers.

The fiberglass geogrids offer high strength, high modulus and high temperature resistance for performing high reinforcement ability, and raise the resistance of fiberglass geocomposites against the damages from installation. Moreover, the nonwoven geotextiles increase the liquid asphalt retention capacity of the product. With the geocomposites to reinforce asphalt layers, the pavements can extend their service life and reduce the occurrence rate of reflective cracking under cyclic traffic load. Therefore, asphalt geocomposite is a highly effective and economical solution for road rehabilitation.

Ashpalt Geocomposite Features

• Very Low elongation and high tensile modulus

• Endure high temperatures during the asphalt layer construction process

• Strong bonding to asphalt layers

• Simple and rapid installation

Benefits

- Suitable for all types of asphalt mixes.

- Minimizes both thermal and stress-related reflective cracking.

- Reduces pavement rutting under high ambient temperatures and intense wheel loads.

- Increases the fatigue life of pavements with weak foundations.

- Extends pavement life.

- Provides cost benefits by increasing pavement life cycle.

- Fast, easy installation, and recyclable.

Property | Test Method | 50–50 | 100–100 | 120–120 | |

Unit Weight | g/m2 | 270±10 | 520±20 | 550±20 | |

Ultimate tensile strength(kN/m) | MD |

ASTM D-5261

| 50 | 100 | 120 |

CD | 50 | 100 | 120 | ||

Elongation at Break (%) | MD | 3 | |||

CD | 3 | ||||

Approximate mesh size(mm) | mm | Measured | 12.7×12.7 25.4×25.4 40×40 | ||

Open Area of Grid | % | CWO 22125 | >80 | ||

Shrinkage @375° F for 15min | % | <1 | |||

Melting Point | ℃ | ASTM D-276 | 255 | ||

Spunbond Nonwoven Fabric | g | 30-100 | |||

Roll Width | m | 1-5 | |||

Roll Length | m | 50-200 | |||