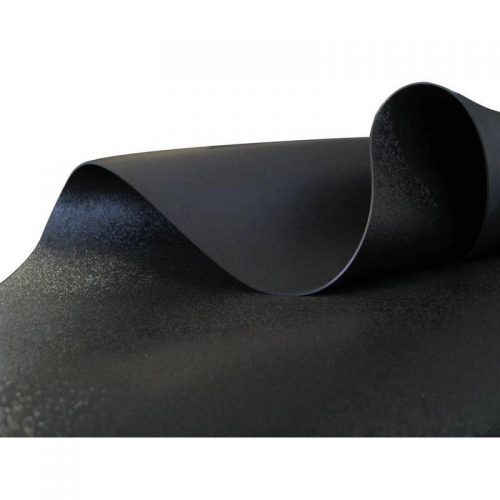

HDPE Geomembrane

HDPE geomembrane liner is the preferred product for lining projects. HDPE geomembrane is resistant to many different solvents and are the most widely used geomembrane liner in the world. Although HDPE geomembrane is less flexible than LLDPE, it provides higher specific strength and can withstand higher temperatures. Its exceptional chemical and ultraviolet resistance properties make it an extremely cost-effective product.These materials are excellent in retaining water and prevents seepage by creating an Impermeable Liner. Geomembranes provides an effective and efficient solution for waterproofing Save layer on various applications.

Product Features

- Good physical and mechanic performance

- High tearing resistance, strong deformation adaptability

- Puncture-resisting, aging resisting, ultra-violet radiation, oil and salt, and corrosion resistance

- Good adaptability to high and low temperature, non-toxicity, long service life

- Good waterproof, drainage, anti-seepage and damp proof effects

- Complete width and thickness specifications, low cost and easy installation.

Application

- Domestic and Hazardous Waste landfills

- Landfill closures

- Heap leach mining and tailing dams

- Biogas Management

- Floating Covers

- Waste water treatment reservoirs

- Water conveyance channels and reservoirs

- Temporary tanks

- Industrial sludge storage and drying ponds

- Secondary containment

- Architectural ponds and lakes

- Brine evaporation ponds

- Aquaculture ponds

- Food and water grade reservoirs and tanks

Specifications

HDPE Geomembrane

Properties | Test Method | 75 | 100 | 125 | 150 | 200 | 250 |

Thickness | ASTM D 5199 | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50 mm |

Density | ASTM D1505 | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc |

Tensile Properties | ASTM D6693 Type IV | 11 kN/m 20 kN/m 12% 700% | 15 kN/m 27 kN/m 12% 700% | 18 kN/m 33 kN/m 12% 700% | 22 kN/m 40 kN/m 12% 700% | 29 kN/m 53 kN/m 12% 700% | 37 kN/m |

Tear Resistance | ASTM D1004 | 93 N | 125 N | 156 N | 187 N | 249 N | 311 N |

Puncture Resistance | ASTM D4833 | 240 N | 320 N | 400 N | 480 N | 640 N | 800 N |

Stress Crack Resistance | ASTM D5397 (App.) | 300 hr. | 300 hr. | 300 hr. | 300 hr. | 300 hr. | 300 hr. |

Carbon Black Content | ASTM D1603 | 2.0% | 2.0% | 2.0% | 2.0% | 2.0% | 2.0% |

| Oxidative Induction Time (OIT) | ASTM D3895 | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. |