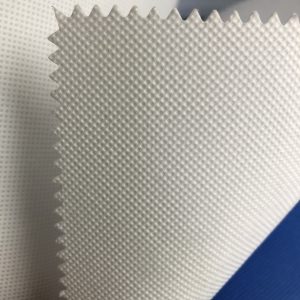

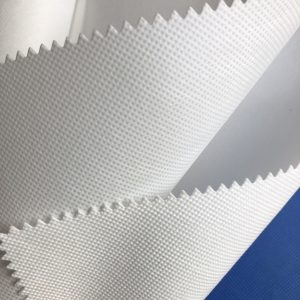

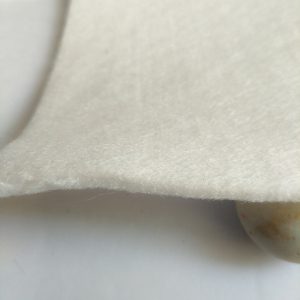

PET Needle Punched Nonwoven Geotextile

PET Nonwoven Needle Punched Geotextiles Fabric is a nonwoven needle punched polyester paving geotextiles, which provides stress relief, waterproofing and reduces reflective cracking functions in new and existing paved roads.

The unique properties of these Nonwoven Geotextiles provide waterproofing and stress relief of the pavement structure. The high melt temperature of Polyester (PET) ensures that the geotextiles properties are not affected by the application of hot bitumen or asphalt.

Product Features

- Polyester Nonwoven Geotextile has good air and water permeability to let water flow through it so as to effectively control sandrock running-down.

- .Geotextile has good water transmissibility, it can form drainage channels inside soil mass to drain redundant liquid and air out of the soil mass.

- Geotextile helps to enhance the soil mass’ tensile strength and non-deformability and structural stability so as to improve soil mass quality.

- It can effectively make the concentrated stress diffuse, transfer or decompound, and prevent the soil mass against the destruction of outside force.

- It can prevent the mixture of sandstone, soil mass and concrete of upper and lower layers.

- Its mesh is hard to jam by virtue of the compliancy and motility of the reticulation formed by indefinite form fibrous tissue.

- High water permeability-it can keep good water permeability even in the pressure of soil and water.

- Corrosion resistant-it is made from polypropylene fiber or terylene or other chemical fiber, featuring resistance to acid and alkali and oxidation, non-corroding, no worm-eaten.

- Easy construction-low weight, easy operation, simple construction.

Nonwoven geotextiles Functions

- Filtration

When water passes from a fine-grained to a coarse grained layer, Non-woven Geotextiles can retain fine particles well. Such as when water flows from a sandy soil into a Geotextile wrapped gravel drain.

- Separation

Separate two layers of soil with different physical properties, such as the separation of road gravel from soft sub-base materials.

- Drainage

TO drain liquid or gas from the plane of the fabric, which leads to draining or venting of the soil, such as the gas vent layer in a landfill cap.

- Reinforcement

To improve the load bearing capacity of a specific soil structure, such as the reinforcement of a retaining wall.

- Specifications

PET Needle Punched Non-woven Geotextile

Index Properties | Test Method | Unit | |||||||||||||

Weight | ASTM D5261 | g/m2 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | |

Ultimate Tensile Strength | ASTM D4595 | ≥kN/m | 2.5 | 3.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 17.5 | 19.0 | |

Tensile Elongation | ASTM D4595 | % | 50 | ||||||||||||

Grab Tensile Strength | ASTM D4632 | ≥N | 225 | 280 | 361 | 641 | 720 | 792 | 911 | 1036 | 1182 | 1346 | 1480 | 1584 | |

Grab Elongation | ASTM D4632 | % | 50 | ||||||||||||

Trapezoid Tear Strength | ASTM D4533 | ≥N | 80 | 100 | 120 | 160 | 200 | 240 | 280 | 330 | 380 | 420 | 440 | 460 | |

CBR Puncture Strength | ASTM D6241 | ≥kN | 0.3 | 0.4 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 2.9 | 3.2 | |

Puncture Resistance | ASTM D4833 | ≥N | 82 | 99 | 133 | 225 | 284 | 346 | 440 | 530 | 596 | 603 | 663 | 760 | |

Drop Cone Resistance(hole-φ) | BS EN 918 | mm | 45 | 40 | 37 | 34 | 31 | 26 | 23 | 19 | 18 | 16 | 15 | 15 | |

| Hydraulic Properties | |||||||||||||||

Apparent Opening Size O90 | ASTM D4751 | ≤mm | 0.13 | 0.12 | 0.12 | 0.12 | 0.12 | 0.11 | 0.10 | 0.09 | 0.08 | 0.08 | 0.08 | 0.08 | |

Permeability | ASTM D4491 | cm/s | 0.41 | 0.41 | 0.41 | 0.41 | 0.40 | 0.40 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | |

| Physical Identification Properties | |||||||||||||||

Thickness | ASTM D5199 | mm | 1.0 | 1.3 | 1.7 | 2.1 | 2.4 | 2.5 | 2.8 | 3.0 | 3.2 | 3.5 | 3.6 | 3.8 | |

Roll Width | – | m | 4-6 | ||||||||||||

Approx Load Qty per 40HQ | M2 | 72000 | 57600 | 48000 | 36000 | 28800 | 24000 | 20400 | 18000 | 15600 | 14000 | 13200 | 12000 | ||