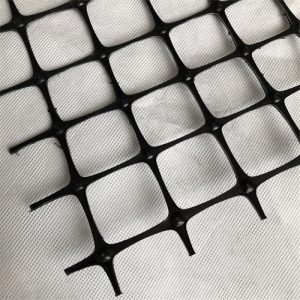

PP Biaxial Geogrid for Pavement is made of high molecular polymer through extrusion, forming and punching before

longitudinal and lateral stretching. This material has considerable tensile strength in longitudinal and lateral directions.

Performance:

High tensile strength at both longitudinal and transverse direction .

Application:

1. It can be applied in all kinds of roads, railways, airports to enhance the roadbed.

2. It can be applied in a large car park and terminal freight yard, etc. to strengthen the foundations of a permanent load;

3. It can be applied in rail, road slope’s protection;

4. It can be applied to enhance the culvert;

5. It can be applied as a secondary enhancement after the uniaxial geogrid soil enhancement, further enhancement to the

soil; prevent soil erosion;

6. It can be applied in mining, tunnel reinforcement.

Benefits:

1. Increase the bearing capacity of the roadbed and foundation and prolong their service life.

2. Prevent road surface and foundation from sinking or flawing, keep clean and beautiful ground surface.

3. Convenient construction saves time and labor, reduce mounting time and decrease maintenance expense.

4. Prevent culverts from flawing.

5. Enhance earth slope and prevent water loss and soil erosion.

6. Decrease underlayer thickness and save manufacturing cost.

7. Enhance the stability of side slope turf net patch to improve greening.

8. Replace wire netting used in mine as intermediate ceiling netting.