PP Geogrid composite

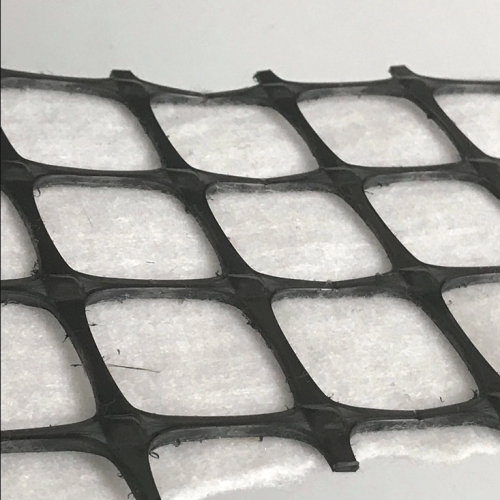

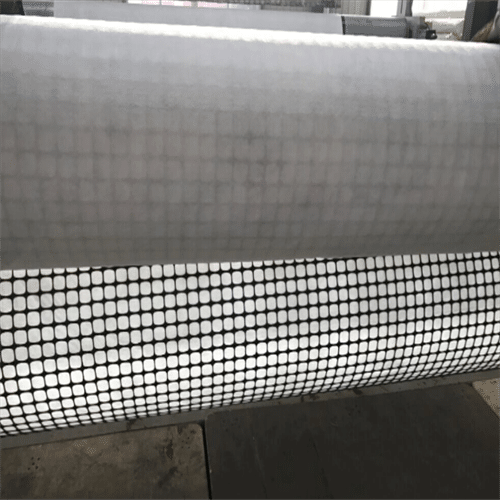

PP geogrid composite is an innovative geosynthetic material engineered by combining polypropylene (PP) geogrids with non-woven geotextiles or other functional layers.

This composite integrates the high tensile strength of geogrids with the filtration, separation, and drainage capabilities of geotextiles, making it a versatile solution for civil engineering applications. Manufactured through advanced processes like ultrasonic welding or hot melting, the product ensures structural integrity and long-term durability.

Key Features

- High Strength & Stability: The PP geogrid component is reinforced with fibers and processed through high-strength stretching and ultrasonic welding, providing exceptional tensile strength (low elongation ≤12%) and resistance to deformation.

- Corrosion Resistance: Resistant to acids, alkalis, and environmental degradation, ensuring a service life exceeding 100 years in permanent projects.

- Eco-Friendly: Made from recyclable PP materials, aligning with sustainable construction practices.

- Ease of Installation: Lightweight and flexible, enabling quick deployment with minimal labor requirements, reducing project timelines and costs.

Technical Advantages

- Dual Functionality: Combines reinforcement (geogrid) with filtration/separation (geotextile), ideal for complex soil stabilization and load distribution.

- Enhanced Drainage: The composite structure facilitates efficient water flow, preventing soil saturation and erosion in applications like roadbeds and slopes.

- Adaptability: Suitable for both new constructions and retrofitting existing infrastructure, such as road widening or subgrade reinforcement.

Applications

PP geogrid composite is widely used in:

- Transportation Infrastructure: Reinforcing highways, railways, and airport runways to reduce uneven settlement and enhance load-bearing capacity.

- Slope Protection: Stabilizing embankments, dams, and coastal structures to prevent soil erosion.

- Urban Engineering: Strengthening retaining walls, landfill liners, and subsurface drainage systems.

Benefits:

1. Increase the bearing capacity of the roadbed and foundation and prolong their service life.

2. Prevent road surface and foundation from sinking or flawing, keep clean and beautiful ground surface.

3. Convenient construction saves time and labor, reduce mounting time and decrease maintenance expense.

4. Prevent culverts from flawing.

5. Enhance earth slope and prevent water loss and soil erosion.

6. Decrease underlayer thickness and save manufacturing cost.

7. Enhance the stability of side slope turf net patch to improve greening.

8. Replace wire netting used in mine as intermediate ceiling netting.