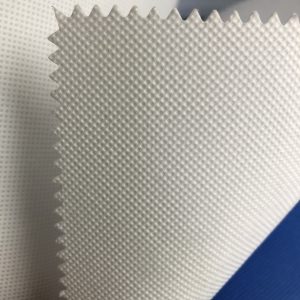

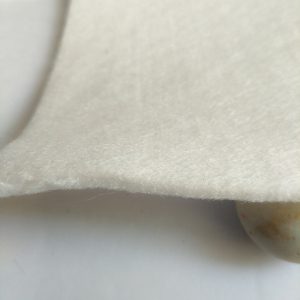

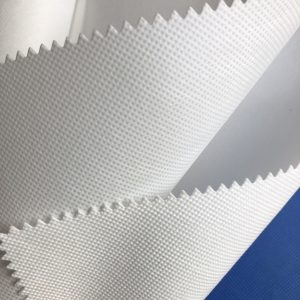

PP Needle Punched Nonwoven Geotextile

Nonwoven geotextiles are multi-purpose fabrics that are felt-like in appearance. PP needle punched geotextile is manufactured from short synthetic fabric (polypropylene fiber).The product is formed after the processes of opening,combing,mixing and disordering,lapping and needling.

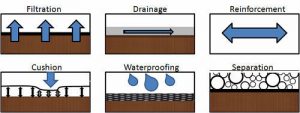

PP Nonwoven Geotextiles has good impermeability and resistance to deformation, which allows geotextiles be widely applied in civil projects for separation,filtration,reinforcement, protection and drainage.

PP Nonwoven geotextiles are used as separation fabrics when higher water flow is required for the application. This can include acting as a separator between the drainage gravel backfill behind a retaining wall, wrapping the stone surrounding the pipe in a french drain, or as an underlayment below riprap. Nonwoven geotextiles can also be treated to resist water flow and used as a pavement underlay by binding with the asphalt to create a barrier to water.

Nonwoven Features

- Excellent drainage performance

- High strength,excellent tenacity

- Anti-aging,anti-acid and alkali

- Can accommodate irregular deformations

- Creep, corrosion and abrasion resistance

- Safe and easy for construction

Nonwoven Applications

Nonwoven geotextiles have a wide range of applications in civil environmental engineering and construction projects.

- Filtration

When water passes from a fine-grained to a coarse grained layer, Non-woven Geotextiles can retain fine particles well. Such as when water flows from a sandy soil into a Geotextile wrapped gravel drain.

- Separation

To separate two layers of soil with different physical properties, such as the separation of road gravel from soft sub-base materials.

- Drainage

To drain liquid or gas from the plane of the fabric, which leads to draining or venting of the soil, such as the gas vent layer in a landfill cap.

- Reinforcement

To improve the load bearing capacity of a specific soil structure, such as the reinforcement of a retaining wall.

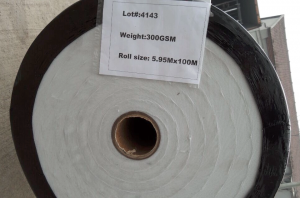

Specifications

PP Needle Punched Non-woven Geotextile

| Index Properties | Test Method | Unit | |||||||||||||

| Weight | ASTM D5261 | g/m2 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | |

| Ultimate Tensile Strength | ASTM D4595 | ≥kN/m | 3.5 | 5.0 | 6.0 | 8.5 | 11 | 13 | 15 | 18.5 | 21 | 23 | 26 | 28 | |

| Tensile Elongation | ASTM D4595 | % | 50 | ||||||||||||

| Grab Tensile Strength | ASTM D4632 | ≥N | 270 | 360 | 460 | 550 | 750 | 930 | 1040 | 1180 | 1350 | 1400 | 1560 | 1720 | |

| Grab Elongation | ASTM D4632 | % | 50 | ||||||||||||

| Trapezoid Tear Strength | ASTM D4533 | ≥N | 110 | 140 | 165 | 220 | 275 | 330 | 385 | 445 | 505 | 560 | 616 | 640 | |

| CBR Puncture Strength | ASTM D6241 | ≥N | 500 | 770 | 1120 | 1600 | 2150 | 2430 | 2920 | 3390 | 3700 | 4110 | 5300 | 5500 | |

| Puncture Resistance | ASTM D4833 | ≥N | 141 | 201 | 261 | 382 | 454 | 565 | 726 | 817 | 931 | 970 | 1028 | 1130 | |

| Drop Cone Resistance(hole-φ) | BS EN 918 | mm | 39 | 36 | 33 | 30 | 27 | 24 | 20 | 16 | 15 | 15 | 14 | 13 | |

| Hydraulic Properties | |||||||||||||||

| Apparent Opening Size O90 | ASTM D4751 | ≤mm | 0.13 | 0.12 | 0.12 | 0.12 | 0.12 | 0.11 | 0.10 | 0.09 | 0.08 | 0.08 | 0.08 | 0.08 | |

| Permeability | ASTM D4491 | cm/s | 0.41 | 0.41 | 0.41 | 0.41 | 0.40 | 0.40 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | |

| Physical Identification Properties | |||||||||||||||

| Thickness | ASTM D5199 | mm | 1.0 | 1.3 | 1.7 | 2.1 | 2.4 | 2.5 | 2.8 | 3.0 | 3.2 | 3.5 | 3.6 | 3.8 | |

| Roll Width | – | m | 4-6 | ||||||||||||

| Approx Load Qty per 40HQ | M2 | 72000 | 57600 | 48000 | 36000 | 28800 | 24000 | 20400 | 18000 | 15600 | 14000 | 13200 | 12000 | ||

Package Details

- PE film or PP woven bag for outpackage or as your reqeust.