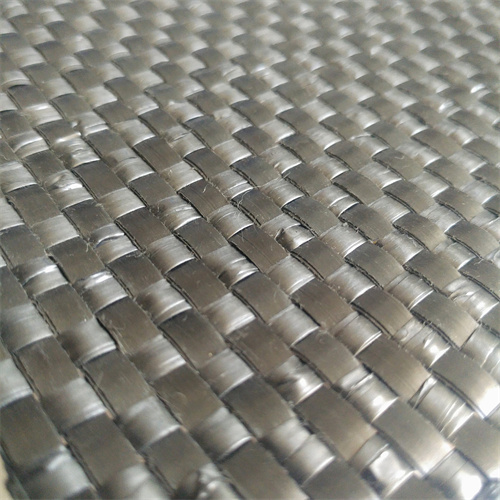

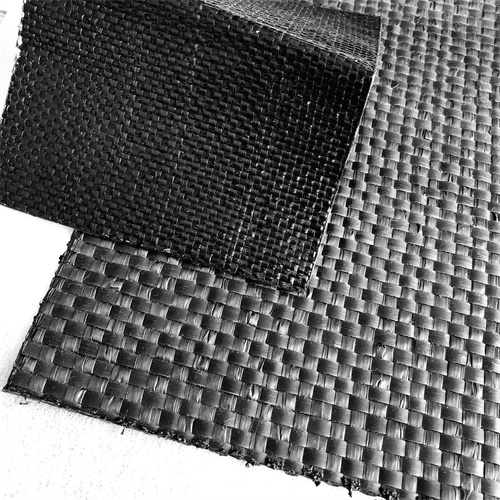

PP Woven Geotextile

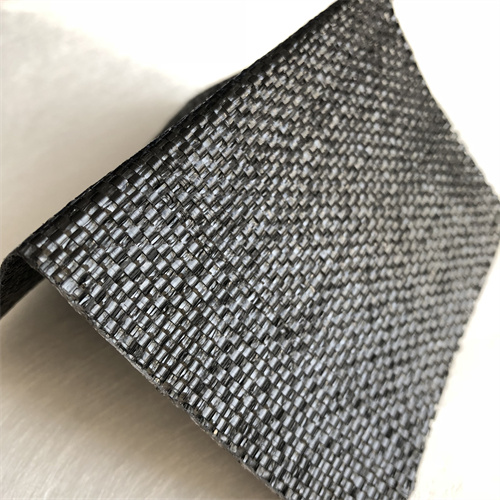

- PP Woven Geotextiles are composed from synthetic polypropylene/polyester fibers through a mechanical process of needling the fabric and adding, when necessary, a thermo fused process, resulting in a uniform porous structure with excellent tensile strength and chemical deterioration.

Product Features

- Eco-friendly

- Non-toxic

- UV protection

- Durable tear-resistance

- Easy to cover with light weight

Application

- Weed Control

Excellent weed control and insect prevention, reduce weedicide use to provide organic soil and healthy food.

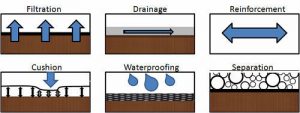

- Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

- Separation:

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

- Reinforcement:

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

- Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Specifications

PP Woven Geotextile

Item | Unit | Index | ||||||||||

Specifications | g/m2≥ | 120 | 175 | 230 | 260 | 280 | 340 | 400 | 460 | 520 | 580 | 640 |

| Longitude Breaking Strength | KN/M≥ | 20 | 30 | 40 | 50 | 60 | 80 | 100 | 120 | 140 | 160 | 180 |

Latitude Break Strength | KN/M≥ | Per agreement, latitude strength is 0.7~1 times of longitude strength if there is no special requirement. | ||||||||||

Breaking Elongation | %≤ | 28 | ||||||||||

| CBR Ejection Force | KN≥ | 1.6 | 2.4 | 3.2 | 4.0 | 4.8 | 6.0 | 7.5 | 9.0 | 10.5 | 12.0 | 13.5 |

| Equivalent Bore Diameter O90(O95) | mm | 0.07~0.5 | ||||||||||

| Vertical Filtration Coefficient | cm/s | 1×(10-1~10-4) | ||||||||||

Anti-UV force retaining rate | %≥ | 70(500h) or as per requirements of design or contract. | ||||||||||